Drinking water, Gestion, Guinea, réservoir, Réservoirs, Uncategorized, Water supply systems

GUINEA: Treatment of surface waters to provide 60,000 rural people with drinking water

A first experience in the treatment of surface waters

The Ministry for Energy and Hydraulics in the Republic of Guinea just announced the awarding of the supply and installation contract to the joint venture composed of ALTECH SAFS (Liège, Belgium) and VERGNET HYDRO (subsidiary of the ODIAL SOLUTIONS Group, Orléans, France) for the construction of drinking water supply systems for 60,000 villagers belonging to 120 remote rural communities spread in the 8 Guinean administrative regions. The 120 sites will be operating by July 2021. “This project is the first experience of VERGNET HYDRO, historical player for groundwater pumping and small water piping in Sub-Saharan Africa, in the surface waters valorization”, says enthusiastically Thierry BARBOTTE, Managing Director for VERGNET HYDRO.

Why treat surface water (village wells, rivers, marshes, etc.) instead of exploiting groundwater, which requires less treatment? Simply because the possibility of drilling on each of these 120 sites has already been rejected. “Either these villages are inaccessible to the equipment that would allow drilling, because they are very remote and their access roads are too complex, or their hydrogeological conditions do not allow satisfactory drilling boreholes“, specifies Baptiste GADENNE, business manager for VERGNET HYDRO.

120 HYDROPUR treatment units

HYDROPUR treatment units, designed and manufactured by ALTECH SAFS, will be set up at each of the 120 sites to treat these surface waters. 20 of which are already in operation in Guinea. The HYDROPUR installations occupy about 20 m² and combine the techniques of treatment by coagulation, flocculation, disinfection by bleach, then filtration on sand and activated carbon. Each unit can treat 1 to 2 m3 per hour, i.e. supply water up to 250 to 1000 people. “The main advantages of a HYDROPUR station are the autonomy, because the treatment is done gravitarily, its robustness, because its structure is in stainless steel, and its simplicity of maintenance“, adds Claude LOMBART, ALTECH SAFS Board Member.

In this project, VERGNET HYDRO identifies, designs and equips the surface water catchment points, locates the HYDROPUR units, organizes the logistical access modalities to the sites for all the equipment, sets up the devices for fetching water to the stations (pumping, piping, solar energy, etc.), and coordinates the construction of the HYDROPUR installation platform. “Taken into consideration the remoteness of the sites and the water quantities expected on each of them (average of 8 m3 to 10m³ per day), we have agreed to systematically convey surface water to the stations by solar pumping“, explains Joël MENAGER, Project Manager at VERGNET HYDRO.

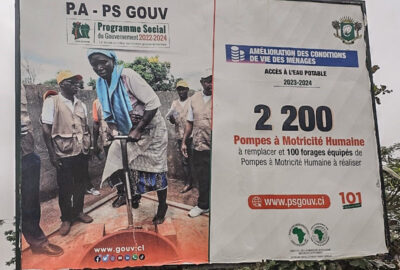

Guinean workers installing a HYDROPUR unit (photos credits: ALTECH SAFS).

A network of mechanics and After-Sales Service shops

Final site selection is scheduled for early July 2018. Whatever the site, the first priority is to establish the water catchment and treatment points. “Before identifying the technical features of each site (topography, geology, hydrology, position of villages in relation to water sources, in order not to disturb farming and/or forest areas, etc.), we will of course go into contact with the populations to integrate their expectations and habits. The social intermediation phase will be determining for the success of such a project calls“, summarizes Baptiste GADENNE. The works will then be carried out in partnership with the Guinean company ENTREPRISE VERGNET GUINEE (Kindia, Republic of Guinea), historic local partner of VERGNET HYDRO, and with the support of National Agency of Hydraulics (Ministry of Energy and Hydraulics of the Republic of Guinea), delegated project manager for this project.

To ensure the durability of the installations, the joint venture will set up a network of repairers and after-sales services shops, similar to the VERGNET HYDRO product after-sales service model. The associations of users of these water points will be able to count on the skills of local repairers, trained ad certified to ensure the maintenance and repairs of their installations: renewal of treatment consumables, equipment maintenance, etc. The project therefore includes a substantial training component for these repairers. “The proximity and the qualification of these craftsmen repairers guarantee a reactive and effective after-sales service”, emphasises Adama DIALLO, General Manager of ENTREPRISE VERGNET GUINEE.

The transfer of the HYDROPUR technology

The “training” component of the project also includes the structuring of user associations into Water Utility Management Units (UGSPE). Villagers will be trained in the routine maintenance of a HYDROPUR and accompanied in the organization of this collegial and regular management. “Basically, this project aims to transfer HYDROPUR technology to Guinea. Not only we are going to train local technicians in the installation and management of HYDROPUR, but we will also gradually implement in Guinea the production of all parts for drinking water treatment plants“, states Claude LOMBART.

The project is financed by an interest-free loan from the Belgian government to the Guinean government. It will last 5 years and will include a first phase of installation of all 120 sites (3 years) and a second phase of site monitoring (over 2 years), knowing that the Belgian development agency ENABEL will follow the project and carry out a general mid-term evaluation. “The timetable is ambitious because we have to deal with the uniqueness of each of the sites, the rainy seasons, the distances between villages, etc.”, concludes Thierry BARBOTTE.